Industrial Automation

In industrial automation solutions driven by the RK3588, Kiwi Pi provides a comprehensive suite of high-performance technologies. These include intelligent control systems, real-time monitoring devices, advanced robotics, and predictive maintenance platforms. Utilizing the RK3588's powerful processing capabilities, these solutions facilitate seamless integration, enhance operational efficiency, and enable precise control over manufacturing processes. By leveraging cutting-edge AI and IoT functionalities, Kiwi Pi's solutions help industries optimize productivity, reduce downtime, and achieve greater automation in the industrial sector.

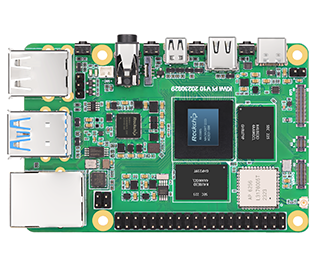

Related Products

Applications

-

The RK3588's multi-core CPU architecture and hardware-accelerated processing capabilities enable real-time control of industrial processes and machinery. Whether it's closed-loop control loops, motion control systems, or robotics applications, the RK3588 provides the computational power and low-latency communication interfaces required for precise and responsive control.

The RK3588's multi-core CPU architecture and hardware-accelerated processing capabilities enable real-time control of industrial processes and machinery. Whether it's closed-loop control loops, motion control systems, or robotics applications, the RK3588 provides the computational power and low-latency communication interfaces required for precise and responsive control.Real-time Control

-

Designed for industrial applications, the RK3588 offers robustness and reliability to withstand harsh environmental conditions such as temperature extremes, vibration, and electromagnetic interference (EMI). Its rugged construction and industrial-grade components ensure long-term operation in demanding industrial environments without compromising performance or durability.

Designed for industrial applications, the RK3588 offers robustness and reliability to withstand harsh environmental conditions such as temperature extremes, vibration, and electromagnetic interference (EMI). Its rugged construction and industrial-grade components ensure long-term operation in demanding industrial environments without compromising performance or durability.Robustness and Reliability

-

The RK3588 can integrate support for various industrial protocols such as Modbus, Profibus, EtherCAT, and OPC UA, enabling interoperability with existing industrial automation systems and equipment. This ensures compatibility and integration with a wide range of sensors, actuators, PLCs (Programmable Logic Controllers), and SCADA (Supervisory Control and Data Acquisition) systems.

The RK3588 can integrate support for various industrial protocols such as Modbus, Profibus, EtherCAT, and OPC UA, enabling interoperability with existing industrial automation systems and equipment. This ensures compatibility and integration with a wide range of sensors, actuators, PLCs (Programmable Logic Controllers), and SCADA (Supervisory Control and Data Acquisition) systems.Industrial Protocols Support